Cheesemaking is the art of transforming milk into delicious creations, from creamy brie to crumbly cheddar. This process combines science and tradition to produce the diverse types of cheese we enjoy today. From fermentation to aging, each step plays a vital role in shaping texture, flavour, and character.

This guide provides a step-by-step overview of the cheesemaking process, covering the essential tools, techniques, and stages involved. Instead of focusing on a specific recipe, it explains how milk transforms into various types of cheese through fermentation, coagulation, and ageing.

For a hands-on recipe, explore our detailed guide on making homemade ricotta cheese here.

Wikipedia’s page on Cheese can provide a broad overview of the history, global varieties, and cultural significance of cheese.

Essential Ingredients and Their Roles

To create high-quality cheese, selecting the right ingredients is crucial to achieving the desired flavour, texture, and consistency. Each ingredient plays a specific role in transforming milk into cheese.

In this section, we break down the essential ingredients you’ll need for cheesemaking and explain their individual roles in the process, helping you understand how they contribute to the final product.

- Milk

- Role: The foundation of cheese. Milk can come from cows, goats, sheep, or buffalo, with each offering distinct flavours and textures.

- Key Note: Pasteurized milk ensures safety, but raw milk retains more natural flavours. Ultra-pasteurized milk should be avoided as it doesn’t form proper curds.

- Starter Culture

- Role: Introduces beneficial bacteria to ferment lactose into lactic acid, which acidifies the milk. This process helps curdling and contributes to the tanginess and texture of the cheese.

- Types:

- Mesophilic: For low-temperature cheeses (e.g., cheddar, gouda).

- Thermophilic: For high-temperature cheeses (e.g., Parmesan, Swiss).

- Rennet

- Role: A coagulating agent that solidifies milk proteins, separating curds (solids) from whey (liquids).

- Sources:

- Animal-based: Traditionally extracted from calf stomachs.

- Microbial or plant-based: Suitable for vegetarians.

- Salt

- Role: Enhances flavor, preserves cheese by controlling moisture, and prevents unwanted microbial growth.

- Application Methods:

- Mixed into curds.

- Rubbed on the cheese surface.

- Used as a brine soak for specific cheeses (e.g., feta).

Basic Equipment and Their Functions

To successfully make cheese, having the right equipment is essential for each stage of the process. Below, we highlight the basic tools you’ll need and their functions to ensure you can craft cheese with precision and ease.

- Large Pot

- Function: For heating milk evenly. Stainless steel or non-reactive pots are ideal to prevent reactions with acidic milk.

- Thermometer

- Function: Precise temperature control is crucial for acidification, coagulation, and heating. Cheesemaking typically requires maintaining temperatures between 86–140°F (30–60°C).

- Cheesecloth

- Function: A fine mesh is used to strain curds from whey and to form soft cheeses like ricotta.

- Slotted Spoon and Knife

- Function: Stirring curds gently prevents breaking, and knives are used to cut curds uniformly to control moisture loss. Smaller cuts yield firmer cheeses.

- Mold and Press

- Function: Molds shape the cheese, while presses remove excess whey and compact the curds. The pressure level determines the cheese’s final texture, from soft (brie) to hard (Parmesan).

- Brining Container

- Function: A vessel to soak the cheese in a saltwater solution, ensuring even salting for varieties like feta or halloumi.

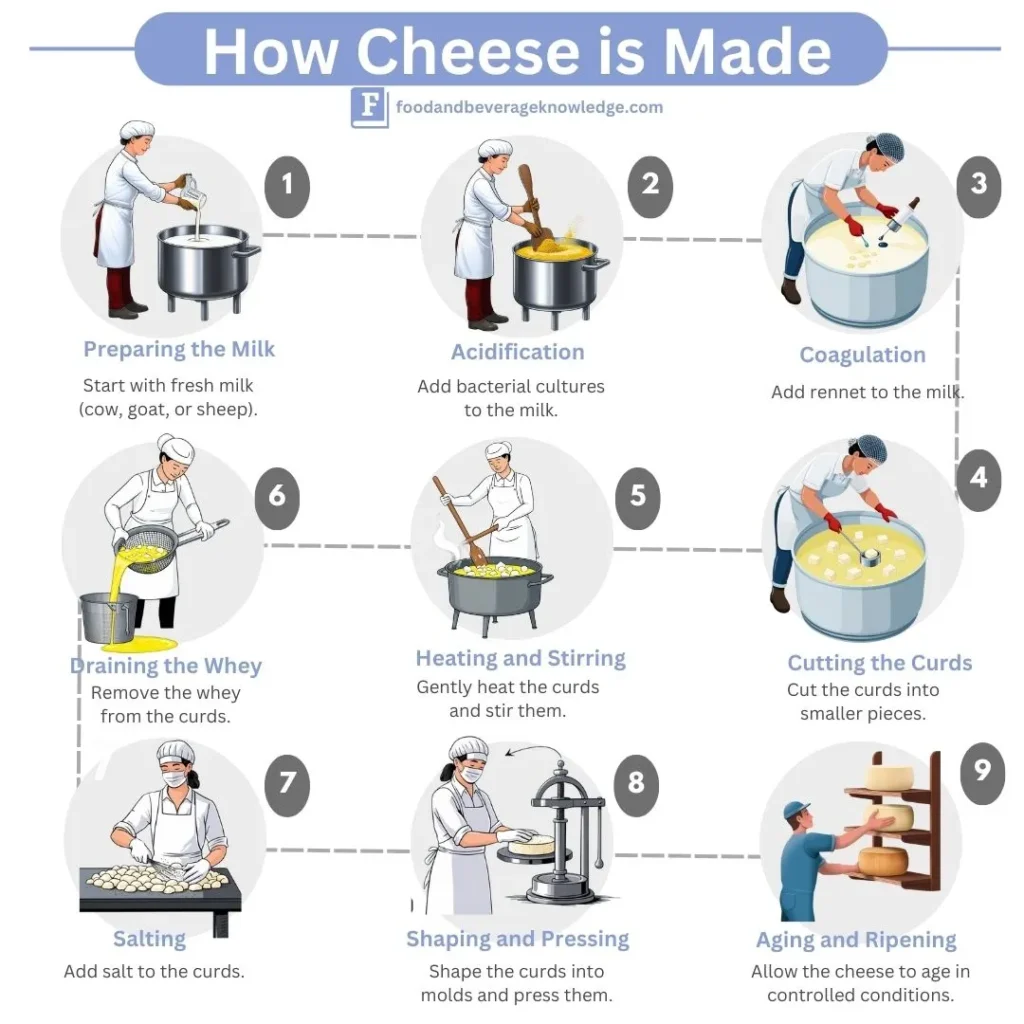

9 Steps of Cheesemaking: A Detailed Process

Cheesemaking is a step-by-step process that demonstrates how to make cheese by transforming milk into a variety of textures and flavours. Below, we explore the nine essential steps, focusing on the techniques and natural transformations that make this ancient craft so unique.

Step 1: Preparing the Milk

The cheesemaking journey begins with high-quality milk, which can be raw or pasteurized. The milk is gently warmed to create the right environment for bacterial cultures and enzymes to function effectively. This initial step is vital because milk quality directly affects the texture, flavour, and overall success of the cheese.

- Process: Heat the milk to 85–95°F (30–35°C) for soft cheeses or up to 140°F (60°C) for firmer types.

- Key Points:

- Use a thermometer to maintain precise temperature control.

- Avoid ultra-pasteurized milk, as it lacks the structural integrity needed for proper curdling.

- Stir gently to ensure even heating and prevent scorching.

Preparing the milk properly lays the foundation for the rest of the cheesemaking process.

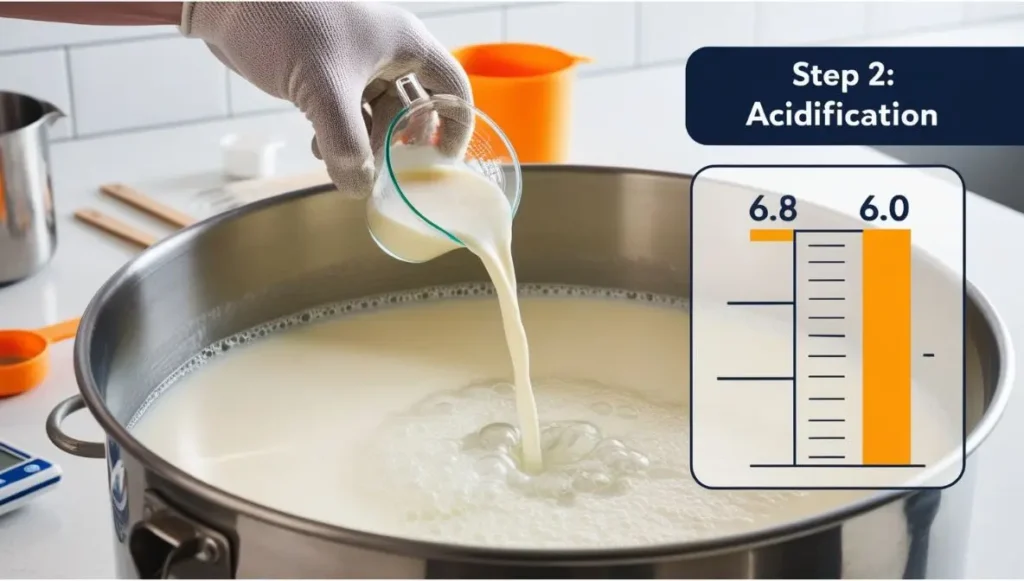

Step 2: Acidification

Acidification is a transformative step where starter cultures are introduced to milk. These cultures contain beneficial bacteria that convert lactose into lactic acid, reducing the pH and setting the stage for curdling. This step is critical for the cheese’s flavour, texture, and shelf life.

- Process: Add the appropriate culture—mesophilic for lower-temperature cheeses or thermophilic for higher-temperature types. Let the milk rest for 30–60 minutes to allow fermentation.

- Key Points:

- Acidification creates a tangy flavour and affects the cheese’s moisture content.

- pH drops to approximately 6.0 during this stage.

- Stir occasionally to distribute the culture evenly.

This step initiates the natural chemical changes that transform milk into curd.

Also Read: Mozzarella cheese | Origins, Production, uses

Step 3: Coagulation

Rennet is added to the acidified milk, causing milk proteins (casein) to coagulate into a gel-like mass. This is the most dramatic transformation in the process, where liquid milk becomes solid curd.

- Process: Add rennet (animal, microbial, or plant-based) and mix gently. Let the milk sit undisturbed for 30–60 minutes.

- Key Points:

- Keep the milk at 85–105°F (29–40°C) for optimal enzyme activity.

- Test for a “clean break” by inserting a knife into the curd—if it separates cleanly, the coagulation is complete.

- Too much or too little rennet can affect texture and flavour.

This step sets the structural foundation for the cheese by forming curds.

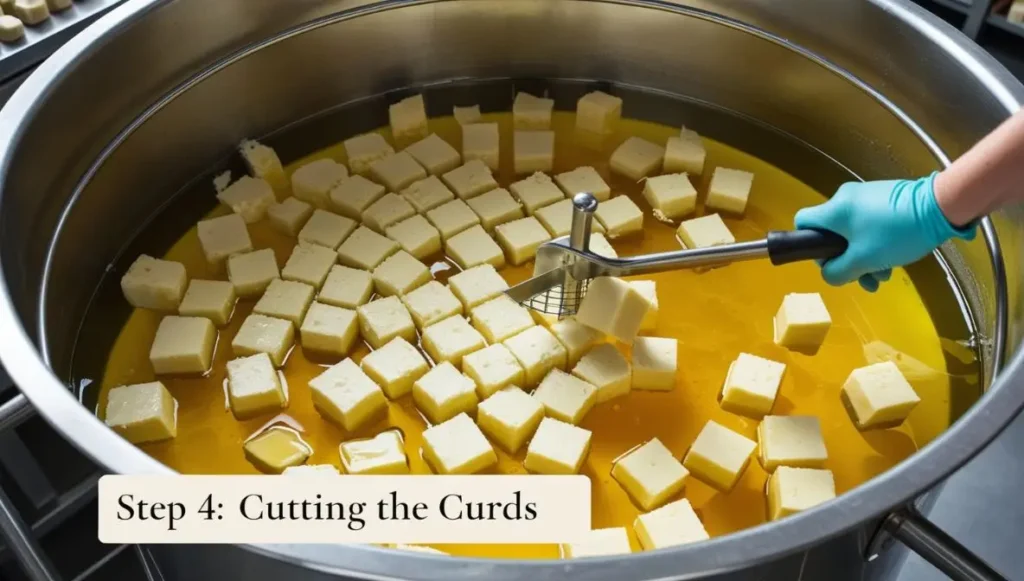

Step 4: Cutting the Curds

Cutting the curds helps release whey and controls the moisture in the cheese. The size of the curds determines the cheese’s texture—smaller curds for hard cheese and larger ones for soft varieties.

- Process: Use a long knife or curd cutter to cut the curds into uniform pieces, typically ½ inch for firm cheeses. Stir gently to prevent breaking them further.

- Key Points:

- Smaller curds release more whey, creating a firmer texture.

- Stirring gently ensures curds maintain their structure while expelling whey.

- Uneven cutting can lead to inconsistent textures in the final product.

Properly cutting the curds ensures the cheese achieves the desired texture and moisture content.

Step 5: Heating and Stirring

This step tightens the curds and expels additional whey, refining the cheese’s texture and firmness. Heating must be done gradually to avoid over-drying the curds.

- Process: Slowly heat the curds to 100–125°F (38–52°C), stirring occasionally to ensure even heating. Continue this process for 20–40 minutes depending on the cheese.

- Key Points:

- Gentle stirring prevents curds from clumping.

- Higher temperatures create firmer cheeses, while lower temperatures retain more moisture.

- Monitor closely to prevent overcooking, which can ruin the texture.

This step determines the final consistency and structure of the curds.

See our guide on: The Ultimate Guide to Danish Blue Cheese

Step 6: Draining the Whey

Draining separates the solid curds from the liquid whey, a crucial step for defining the cheese’s moisture level and texture.

- Process: Transfer the curds to a colander lined with cheesecloth. Allow the whey to drain naturally or by applying light pressure. For soft cheeses, hang the cheesecloth to remove excess whey over time.

- Key Points:

- Excessive draining can dry out the cheese, so monitor it closely.

- Save whey for other uses, such as making ricotta or baking.

- Proper draining helps the curds achieve the right consistency for pressing.

This step concentrates the curds into a cohesive mass, ready for shaping.

Step 7: Salting

Salt enhances the flavour, preserves the cheese, and helps develop the rind. It also plays a role in controlling moisture and preventing unwanted bacterial growth.

- Methods:

- Directly mix salt into curds for fresh cheeses.

- For aged varieties, apply salt to the surface or soak the cheese in a brine solution (16–18% salt).

- Key Points:

- Salt adds flavour and acts as a natural preservative.

- Over-salting can inhibit ageing bacteria, so balance is critical.

- For brining, adjust the time based on cheese size and type.

Salting also impacts the texture by regulating moisture and forming a protective rind.

Step 8: Shaping and Pressing

The curds are moulded and pressed to shape the cheese, and the remaining whey is removed. The pressure applied depends on the type of cheese being made.

- Process:

- Place curds into a mould lined with cheesecloth.

- Apply pressure using a cheese press, starting gently and increasing gradually over hours.

- Pressure levels vary:

- Soft cheese: Light pressing (1–5 lbs).

- Hard cheese: Heavy pressing (10–50 lbs).

- Key Points:

- Soft cheeses need light pressing (1–5 lbs), while hard cheeses require more pressure (10–50 lbs).

- Press evenly to avoid air pockets that can affect ageing.

- Shape consistency impacts the cheese’s appearance and uniformity.

This step gives the cheese its final form and structure.

Also Read: Service of cheese in restaurants

Step 9: Aging and Ripening

This final step transforms cheese into a flavorful, aromatic, and textured product through controlled ageing. Enzymes and bacteria play a key role in breaking down proteins and fats.

- Process:

- Store cheese in an ageing room or fridge at 50–60°F (10–15°C) with 75–90% humidity.

- Flip cheese regularly to ensure even ageing.

- Ageing time varies:

- Fresh cheese: No ageing required.

- Semi-hard: 1–6 months (e.g., gouda).

- Hard: 6–24+ months (e.g., Parmesan)

- Key Points:

- Humidity prevents drying and encourages rind development.

- Regular flipping ensures uniform ripening.

- Longer ageing enhances flavour but can also intensify sharpness.

Ageing is when cheese develops its unique characteristics, completing the cheesemaking process.

Download the cheese production process, PDF for later reading!

Enhance your cheese experience with the right wine, bread, or fruit combinations. Check out pairing tips on Culture Cheese Magazine.

Conclusion

Cheesemaking is an intricate process requiring patience and precision. Each step contributes to the texture, flavour, and variety of cheese. By understanding these universal steps, you’ll gain a deeper appreciation for the craftsmanship behind your favourite cheeses. Whether you try making cheese yourself or enjoy it as a consumer, the journey from milk to cheese is truly extraordinary.

More on Cheese

- Exploring Parmesan or Parmigiano-Reggiano cheese

- The Ultimate Guide to Ricotta Cheese

- Homemade Ricotta Cheese Recipe

- Complete guide to Feta cheese

- Discovering The Cottage Cheese

- The Ultimate Guide to Bel Paese Cheese

- Cream Cheese Essentials: Everything You Need to Know

- 27 different types of cheese: their origin and uses

Subscribe and join our community of hospitality professionals & students — get insights, tips, and the latest updates delivered straight to your inbox!