Beer brewing is an ancient craft, perfected over centuries to produce the wide variety of beers we enjoy today. The process of making beer involves converting grains into sugars, which are then fermented by yeast to create alcohol. Understanding the steps behind this process can give you a deeper appreciation for every sip.

In this comprehensive guide, we’ll explore how beer is made, breaking down each step with clear explanations, educational insights, and visuals to help you grasp the magic behind every pint.

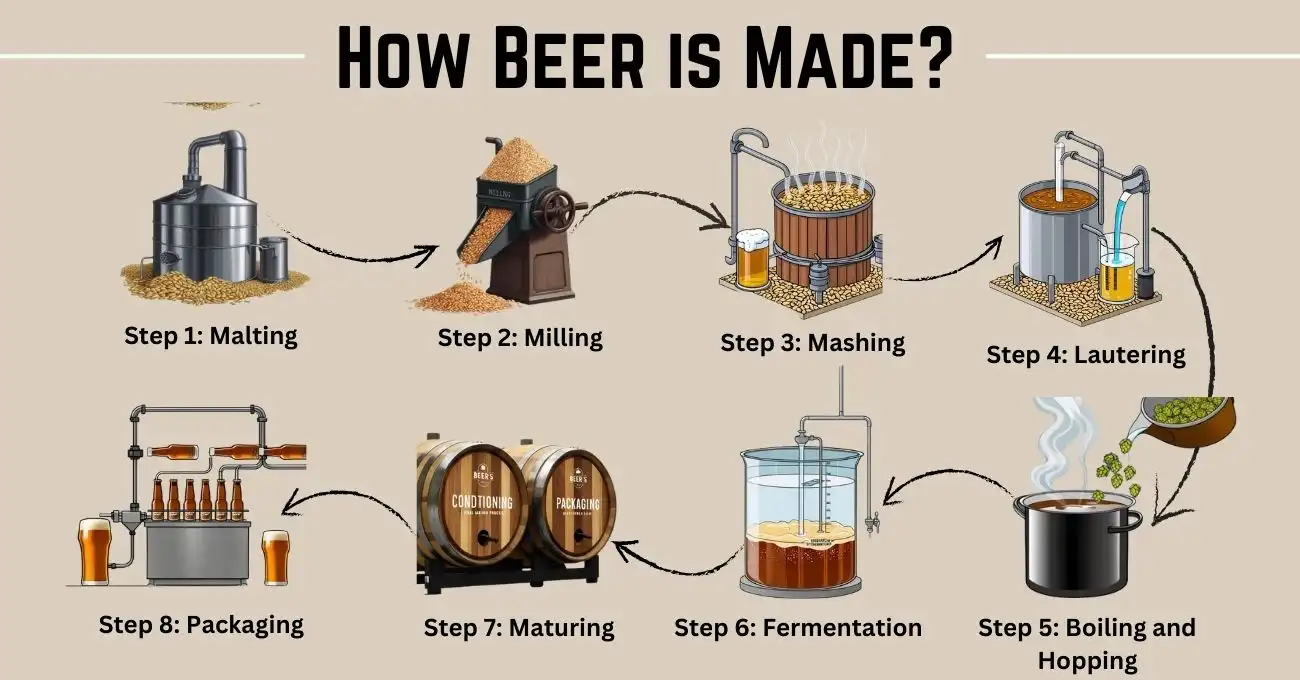

Before diving into the details of how beer is made, take a look at this infographic. It simplifies the 8 key steps, making the entire brewing process easier to understand.”

Table of Contents

- The Essential Ingredients of Beer

- Brewing Process A Step-by-Step Overview

- How Brewing Techniques Vary Between Beer Styles

- Homebrewing vs. Commercial Brewing

- Frequently Asked Questions (FAQ)

The Essential Ingredients of Beer

Beer is created with just four primary ingredients, but their combination produces endless flavor possibilities. Let’s break them down:

- Water: Water makes up about 90% of beer, and its mineral content influences the flavor and brewing characteristics.

- Malt: Malted barley is the most common grain used in brewing, providing the sugars needed for fermentation.

- Hops: Hops are the flowers that give beer its bitterness, balancing the sweetness of the malt. They also add aroma and flavor.

- Yeast: Yeast is the microorganism that ferments the sugars in malt into alcohol and carbon dioxide.

How Beer is Made: Brewing Process step by step

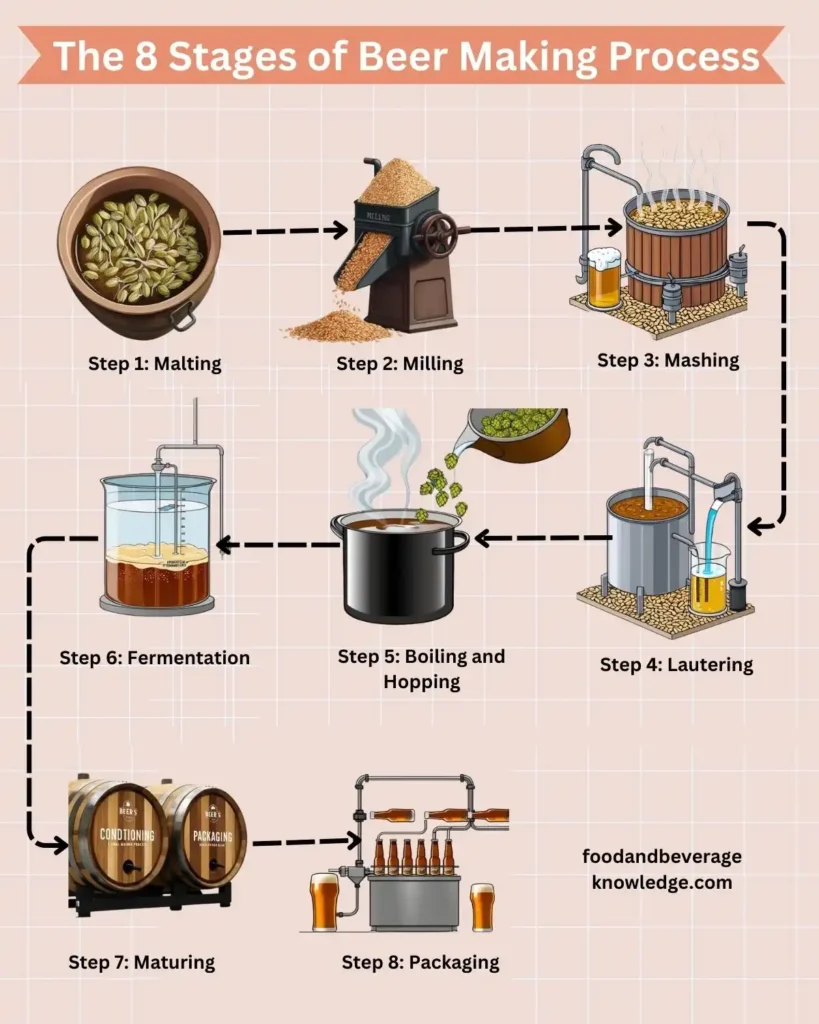

Beer brewing is a carefully orchestrated process that turns simple ingredients like grains, water, hops, and yeast into a beverage enjoyed worldwide. Below are the eight key stages of brewing, along with educational insights to enhance your understanding of each step.

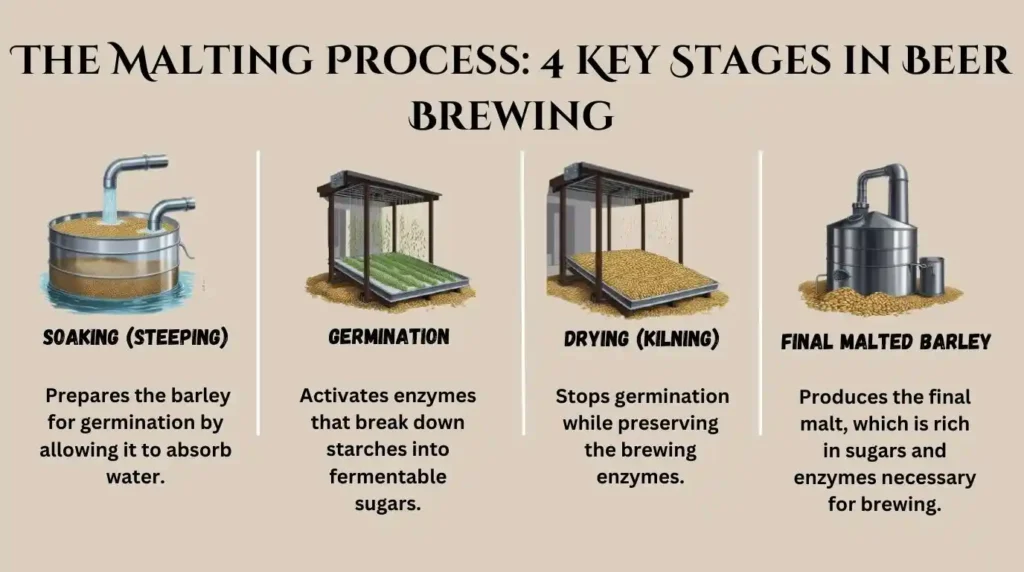

Step 1: Malting

Malting is the first crucial step in the brewing process. It begins with selecting barley or other grains, which are soaked in water to initiate germination.

During germination, the grain’s enzymes break down the stored starches into fermentable sugars.

This is a pivotal phase because these sugars are what yeast will later convert into alcohol during fermentation. After germination, the grains are dried in a kiln, which halts the germination process.

The degree of drying, or roasting, greatly impacts the flavour profile and colour of the malt. Lightly kilned malts produce pale, crisp beers, while heavily roasted malts result in darker beers with richer, more complex flavours.

Essential Stages of Malting:

- Steeping: Barley is soaked in water for 2-3 days, raising its moisture content to around 45%.

- Germination: Grains are spread on malting floors for 4-6 days, allowing the enzymes to convert starches to sugar.

- Kilning/Roasting: The grains are dried in a kiln to stop germination and develop flavours, with roasting times influencing the malt’s final flavour and colour.

Educational Insight: The type of malt used can dramatically affect the beer’s colour and flavour. Pale malts are used for lighter beers, while roasted malts give darker beers their rich tones.

Also Read: Beer Glasses: The Ultimate Guide to Choosing the Right Glassware

For more details, explore Wikipedia’s overview on malting.”

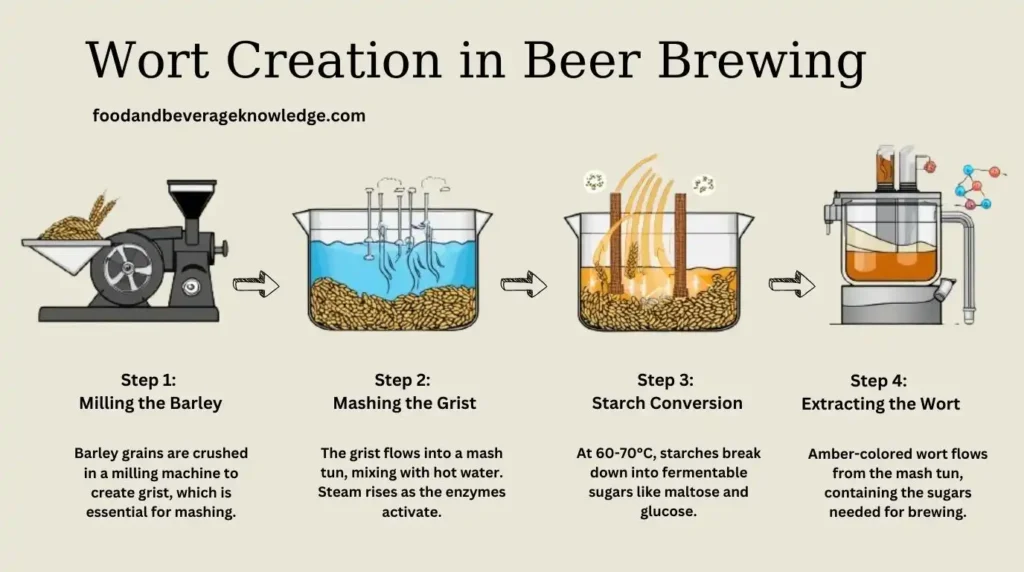

Step 2: Milling

Once the malting process is complete, the malted grains are milled or crushed to break open the grain husks. This process, known as milling, increases the surface area of the malt, allowing more efficient sugar extraction during the mashing phase.

The resulting ground-up grains are referred to as “grist.” The degree of milling is crucial; overly coarse milling can result in poor sugar extraction, while overly fine milling may lead to a thick mash that’s difficult to process.

Proper milling ensures maximum enzyme activity during mashing, directly influencing the beer’s body and alcohol potential. If the grains are milled too finely, the mash can become gummy and hard to filter.

Essential Stages of Milling:

- Setting the Mill: The mill is adjusted based on the grain type and desired coarseness.

- Crushing the Grains: Grains pass through the mill to crack the husk, exposing the starches.

- Grist Collection: The resulting grist is collected in a hopper and transferred to the mash tun.

Educational Insight: Milling breaks open the malt, increasing the surface area for the enzymes to act on. This is critical for extracting the sugars during mashing, directly affecting the beer’s body and alcohol content.

Step 3: Mashing

Mashing involves combining the grist with hot water in a mash tun, allowing the enzymes from the malt to further break down the starches into fermentable sugars. The water temperature is a critical factor in mashing, typically ranging between 60-70°C (140-158°F).

Lower temperatures favour enzyme activity that results in a drier, lighter beer, while higher temperatures yield more complex sugars, creating fuller-bodied, sweeter beers.

The result of mashing is a sugary liquid known as “wort.“

Mashing temperature significantly impacts beer flavour. For instance, lower mashing temperatures result in lighter, more crisp beers like pilsners, while higher temperatures are used for beers like stouts and porters, which are richer and more robust.

Essential Stages of Mashing:

- Doughing-In: Grist is mixed with hot water, ensuring even hydration.

- Saccharification: Enzymes break down the starches into simpler sugars, forming wort.

- Resting: The mash is held at a constant temperature to allow complete sugar extraction.

Educational Insight: The temperature during mashing is crucial. Lower temperatures produce drier beers, while higher temperatures yield sweeter, fuller-bodied beers.

Also Read: 15 Different Types of Beer Glasses

Step 4: Lautering

Lautering separates the wort (the liquid extracted during mashing) from the solid grain particles. This occurs in a lauter tun, where the mash is filtered through a bed of spent grains.

Hot water, called “sparge water,” is often sprayed over the grain bed to rinse out any remaining sugars.

This step is critical for maximizing sugar extraction, which will later determine the beer’s alcohol content. Once lautering is complete, the clear, sweet wort is transferred to the next stage for boiling.

Lautering ensures the wort is clear of solid particles, preventing off-flavours in the final beer. Proper sparging also improves efficiency by extracting as much sugar as possible from the grains.

Essential Stages of Lautering:

- First Wort Runoff: The first wort is collected after it filters through the grain bed.

- Sparging: Hot water is sprayed over the grain bed to extract the remaining sugars.

- Collection of Wort: The wort is collected in the kettle for the boiling phase.

Educational Insight: Lautering is where the wort is separated from the solid grain. Hot water is often poured over the grain to rinse any remaining sugars. This step ensures maximum sugar extraction, which boosts the beer’s potential alcohol content.

Step 5: Boiling and Hopping

The wort is boiled for 60 to 90 minutes, primarily to sterilize the liquid and extract bitterness from the hops. Hops are the flowers of the hop plant, and they provide bitterness, flavour, and aroma to the beer.

The timing of hop additions during the boil affects the final product. Hops added early in the boil contribute more bitterness, while hops added later enhance flavour and aroma.

Additionally, boiling evaporates unwanted volatile compounds, concentrating the flavours in the wort.

Hop varieties vary by region, with American hops typically imparting citrus and pine notes, while European hops offer earthy, herbal tones.

The bitterness level of a beer, measured in IBUs (International Bitterness Units), is controlled by the amount and timing of hop additions.

balances the sweetness of the malt but also contributes to the aroma and acts as a preservative. The timing of hop additions determines how much flavour and bitterness they impart

Essential Stages of Boiling and Hopping:

- Boiling the Wort: The wort is heated to a rolling boil to sterilize it.

- Adding Hops: Hops are added at various points to control bitterness, flavour, and aroma.

- Boil End: The boil is stopped after the desired level of bitterness and flavour is reached.

Educational Insight: Different hop varieties (e.g., American hops vs. European hops) impart unique flavours. American hops tend to be citrusy or piney, while European hops are more earthy and herbal..

Also Read: Top 13 Most Popular Beer Brands in the World

Discover more about hops via Hop Growers of America.”

Step 6: Fermentation

After boiling, the wort is rapidly cooled and transferred to a fermentation tank, where yeast is added. Yeast is a microorganism that consumes the sugars in the wort and produces alcohol and carbon dioxide.

The fermentation process can last anywhere from a few days to several weeks, depending on the yeast strain and desired beer style.

Ale yeasts, which ferment at warmer temperatures, produce fruity and complex flavours, while lager yeasts ferment at cooler temperatures for cleaner, crisper beers.

The fermentation temperature has a profound effect on the beer’s taste. Ales are typically fermented at higher temperatures (15-24°C/59-75°F), producing fruity esters, while lagers ferment at lower temperatures (7-13°C/45-55°F) for a cleaner finish.

Essential Stages of Fermentation:

- Wort Cooling: The wort is cooled quickly to yeast-pitching temperature.

- Yeast Pitching: Yeast is added to the cooled wort, starting the fermentation.

- Primary Fermentation: Yeast converts sugars into alcohol and CO2 over several days.

Educational Insight: The type of yeast used (ale vs. lager yeast) has a significant impact on the beer’s flavour. Ale yeasts ferment at warmer temperatures, producing fruity flavours, while lager yeasts ferment at cooler temperatures for a cleaner, crisper taste.

Fermentation transforms sugars into alcohol, creating beer’s distinct flavours. See Wikipedia’s fermentation explanation.

Step 7: Maturing

After fermentation, the beer undergoes a maturation or conditioning phase, where it ages to develop its flavour profile and clarity. Some beers, such as lagers, require extended conditioning at cold temperatures, while ales may mature more quickly at warmer temperatures.

This stage also allows any remaining yeast and sediment to settle, resulting in a clearer beer. Dry-hopping, or adding hops during maturation, can enhance the beer’s aroma without adding bitterness.

Maturation improves the beer’s stability, clarity, and flavour balance. Some beers are “bottle-conditioned,” meaning they undergo a secondary fermentation in the bottle, which naturally carbonates the beer.

Essential Stages of Maturing:

- Cold Storage: Beer is stored at cold temperatures to condition.

- Dry-Hopping (Optional): Hops may be added to enhance the aroma.

- Clarification: Sediment settles, leaving a clearer beer for packaging.

Educational Insight: Some beers, such as IPAs, are “dry-hopped” during maturing, adding fresh hops to increase aroma without additional bitterness.

Step 8: Packaging

The final step in beer production is packaging. Whether it’s bottled, canned, or kegged, beer must be handled with care to preserve its freshness and carbonation.

Some beers may undergo pasteurization to extend their shelf life, while others are left unpasteurized for a fresher taste.

Proper packaging ensures that the beer reaches the consumer with its intended flavour, aroma, and carbonation intact.

Cans are becoming more popular among craft brewers because they offer better protection against light and oxygen, both of which can degrade the beer’s flavour over time.

Also Read: The Ultimate Guide to Serving Beer: Tips, Techniques, and Best Practices

Essential Stages of Packaging:

- Filtration (Optional): Beer is filtered to remove any remaining yeast or sediment.

- Carbonation: CO2 is added, or natural carbonation occurs in the package.

- Sealing and Labeling: Beer is sealed in bottles, cans, or kegs, ready for distribution.

Educational Insight: Cans are becoming increasingly popular for craft beer due to their superior ability to block light, which can degrade the beer’s taste.

How Brewing Techniques Vary Between Beer Styles

The brewing process may follow the same eight steps, but the specific techniques and ingredients used vary depending on the beer style:

- Lagers vs. Ales: Lagers are fermented at cooler temperatures (45-55°F), using bottom-fermenting yeast, while ales are brewed at warmer temperatures (60-75°F) with top-fermenting yeast. This difference influences the beer’s flavor, with lagers typically having a crisp, clean taste and ales being more robust and fruity.

- Stouts vs. IPAs: Stouts rely on roasted malts to create deep, coffee-like flavors, while IPAs (India Pale Ales) emphasize hop bitterness and aroma. IPAs also involve late or dry-hopping techniques, adding hops after fermentation to enhance aroma without increasing bitterness.

- Wheat Beers: These beers use a large proportion of wheat alongside barley in the mashing process, giving them a lighter body and hazy appearance. They often undergo a shorter fermentation time for a fresh, fruity taste.

Homebrewing vs. Commercial Brewing

The brewing process is similar for both homebrewers and commercial brewers, but there are some key differences in equipment, scale, and precision.

- Homebrewing: Homebrewers often use smaller equipment, such as 5-gallon fermenters and basic temperature controls. The ingredients are usually the same, but the process is simplified.

- Commercial Brewing: Commercial brewers use industrial-sized mash tuns, fermentation tanks, and precision temperature control systems. They can also brew on a much larger scale and with higher consistency.

Frequently Asked Questions (FAQ)

1. What is wort in brewing?

Wort is the sweet liquid extracted from mashing, which contains fermentable sugars for the yeast to turn into alcohol during fermentation.

2. How long does it take to brew beer?

The brewing process can take anywhere from two weeks to several months, depending on the beer style and conditioning time.

3. What role do hops play in beer?

Hops add bitterness to balance the sweetness of the malt. They also provide flavor and aroma and act as a natural preservative.

4. What’s the difference between ales and lagers?

Ales are fermented at warmer temperatures with top-fermenting yeast, while lagers are fermented at cooler temperatures with bottom-fermenting yeast. Ales are typically more fruity and complex, while lagers are cleaner and crisper.

More On Beer:

- How Beer is Made: A Detailed Step-by-Step Guide

- The Ultimate Guide to Draft & Draught Beer: Everything You Need to Know

- 13 Popular Beer Brands in India

- The Ultimate Beer and Food Pairing Guide: The Best Match for Every Beer Type

- Beer Glasses: The Ultimate Guide to Choosing the Right Glassware

- The Ultimate Guide to Serving Beer: Tips, Techniques, and Best Practices

Subscribe and join our community of hospitality professionals & students — get insights, tips, and the latest updates delivered straight to your inbox!